Automotive Bearings

Learn about the different types of bearings used in Automobiles.

Cars' standard bearing suite includes the following:

●Wheel bearing

●Wheel Flange

●Wheel Hub Assembly

●Tensioner Pulley

●Concentric Slave Cylinder

●Clutch Release Bearing

●Air Conditioner Bearing

●Alternator Bearing

●Transmission Bearing

●How does a Wheel Bearing work on a car?

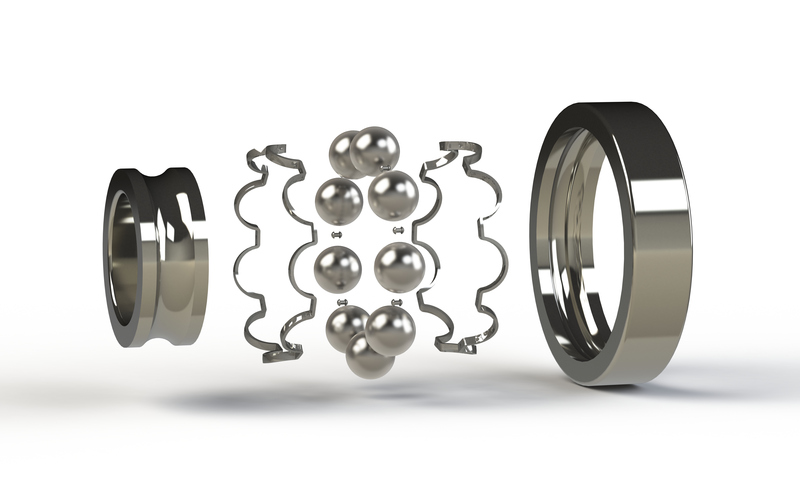

A wheel bearing is a crucial part of the wheel assembly that connects the wheel and the axle. It is a set of steel balls (ball bearings) or tapers (tapered bearings), held together by a metal ring. It enables the wheel to rotate smoothly with a minimum of friction. Wheel bearings are safety critical components designed to sustain radial and axial loads caused by gravitation, acceleration, breaking & cornering forces, so they need to be replaced when they stop working properly.

● What are the differences and applications between Angular Contact Ball Bearings and Tapered Roller Bearings?

Tapered roller bearings and angular contact bearings have different rolling elements. One is a sphere (point contact) and the other is a roller (line contact). Line contact has a large load bearing capacity and strong rigidity. Angular contact mainly bears axial load.

Comparing the two bearings,tapered ones will have a larger contact surface area between the race and rollers than angular ones. With this being said,tapered ones will require more of a clamping force to minimize backlash thus requiring more torque to rotate the bearing. Let's not forget the resistance of the grease and because of the physical size there is a large rotational inertia. They are designed for low speed and heavy loads. Angular contact bearings are smaller, lighter in weight, less rolling friction and will operate at a higher rotational speed.

●What are the symptoms of bad Wheel Bearings?

①Noise:

●A humming, rumbling or growling noise that increases with acceleration or as the vehicle turns.

●A loud constant whining or grinding noise when the vehicle is in motion.

●Clunking noises when driving over uneven road surfaces.

②Looseness, excessive play in the steering wheel (vague steering);

③ABS malfunctioning. ABS system issues can be related to failure of the ABS sensor that is integrated in the wheel end bearing.

●How long does a Wheel Bearing last?

Wheel bearings have an average lifespan of 50000 to 60000 km, This is only a rule of thumb though, the actual lifespan of a wheel bearing depends on the quality of the wheel bearing and the operating conditions.

PRORUN now have more than 3000 numbers including wheel hub unit and wheel bearings, the application is covering various brand cars.

●Wheel Flange OVERVIEW

Wheel flanges come as standard on all motor vehicles and play a key role in the way our cars are driven. Round and flat, these small adapter hubs connect wheel and axle. Theirs is a primary function, preventing tyres from falling off.

●Wheel Flange FACTS

①A Wheel flange allows a wheels to be attached to axle on a vehicle.

②Wheel flanges are mechanically locked to the end of either a drive axle or spindle.

③Wheel flanges, along with lug nuts, have long been the standard mounting method for car wheels.

●Wheel Hub Assembly: What is it?

A wheel hub assembly is also referred to as wheel hub bearing, hub assembly and wheel hub unit. The hub assemblies attached to the wheel of a car helps in moving a vehicle smoothly. They also impact the performance of the anti-lock braking system and fuel economy. Hence, to ensure that the performance of a car is great, all these car wheel parts should function together with ease.

●Tensioner Pulley: What is it and what it is used for?

In a typical timing belt drive configuration, the belt is wrapped around one or more pulleys that always keep it taut and aligned. In today’s article we learn a little more about one of these components, the tensioner pulley, and its importance in the transmission of our vehicle. The timing system is essential to maintaining the good performance of a vehicle. In it, the responsible for achieving a precise transmission and for achieving a proper and constant tension in the belt is none other than the tensioning pulley.

●What are the main functions of Tensioner Pulley?

①Increases the angle embraced in belt drives.

②Gives tension to the belt and transfers the driving force of the crankshaft.

③Compensates for the elongation of the strap, typical over time.

④Allow for shorter wheelbases.

⑤Prevents belt slippage.

●How is a Concentric Slave Cylinder used?

The CSC is usually mounted inside the gearbox bell-housing and is made of modern thermoplastics or aluminum, with intricate rubber seals and chambers within. When a clutch is replaced, it is critical that the CSC is also replaced. After a number of clutch actuation, the rubber seals wear out and the operating position of the CSC changes, indicating that the worn internal components are no longer aligned. To ensure that there is no hydraulic fluid loss, the rubber seals inside CSCs must be of the highest quality. Allowing fluid to pass through the seals contaminates the friction material on the disc, resulting in clutch failure. The CSC should not be compressed before fitting because it will damage the rubber seals because they are not fully lubricated.

●Understanding the Basics: What does a Clutch Release Bearing do?

If there is a significant gap between the rotation centers of the diaphragm spring and the clutch release bearing, self-aligning clutch release bearings prevent abnormal heat and wear. The centering mechanism between the sleeve and bearing absorbs the gap in the rotation center of the diaphragm spring at the start of the clutch release bearing's rotation, and after that the rotation centers of both of them are aligned to suppress abnormal heat generation and wear on the contact surfaces.

Clutch release bearings that use steel plate presses for their bearing rings decrease the overall vehicle weight and contribute to lower fuel consumption.

●How does a Air Conditioner Bearing work?

Designed to accommodate combined loads while with standing vibration, air conditioner ball bearings facilitate the transfer of energy from the engine to the compressor. Their key elements are one outer ring, one inner ring, rolling elements (balls), and cages that are engineered to reduce noise output with increased tolerance to heat. These bearings have raceways in both inner and outer rings which are placed together in the direction of the bearing axis. Always sealed, this bearing type has a longer service life due to less risk of contamination, thus giving reliable air conditioning service to vehicles.

●How is a Alternator Bearing used?

An alternator bearing is a small component that supports the alternator’s rotor shaft. The alternator is responsible for generating electricity to power the car’s electrical systems and recharging the battery. The bearing helps the rotor shaft spin smoothly and reduces friction between moving parts.

●What are the Symptoms of a Faulty Alternator Bearing?

Here are some common symptoms of a faulty alternator bearing:

① Squeaking or grinding noise coming from the engine

②Electrical issues, such as dimming headlights or weak battery

③Burning smell coming from the engine

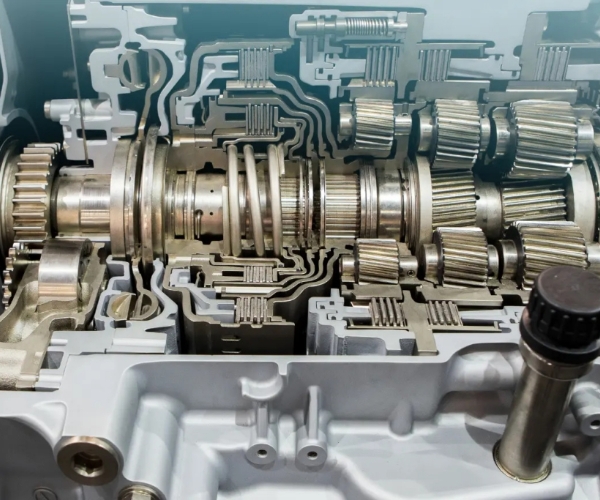

●What are the Car Automatic Transmission Bearings?

Transmission bearing units consist of a housing, bearing and seal that is pre-assembled and greased at the factory. These ready-to-mount units can accommodate moderate initial misalignment but normally do not enable axial displacement of the shaft. Transmission bearing units offer a simple, cost-effective solution that can provide a number of benefits.

There are many types of bearings found in automatic transmission systems. These bearings and washers have a distinctive identity and purpose. For example, the roller and ball bearings are used with shafts that help in high-speed rotations. The role of the bushing is to increase the contact area with the shaft and help in reducing friction. Usually pressed into a case, these bushings have a tight fit. It requires a special installation process and a puller tool for replacement.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Luisa Li

Mobile:+86-18707719045

Tel:86-571-82239356

Email:prorun@prorunparts.com

Add:7th floor, Building 2, Henglong Square, Xiaoshan, Hangzhou, Zhejiang, China.